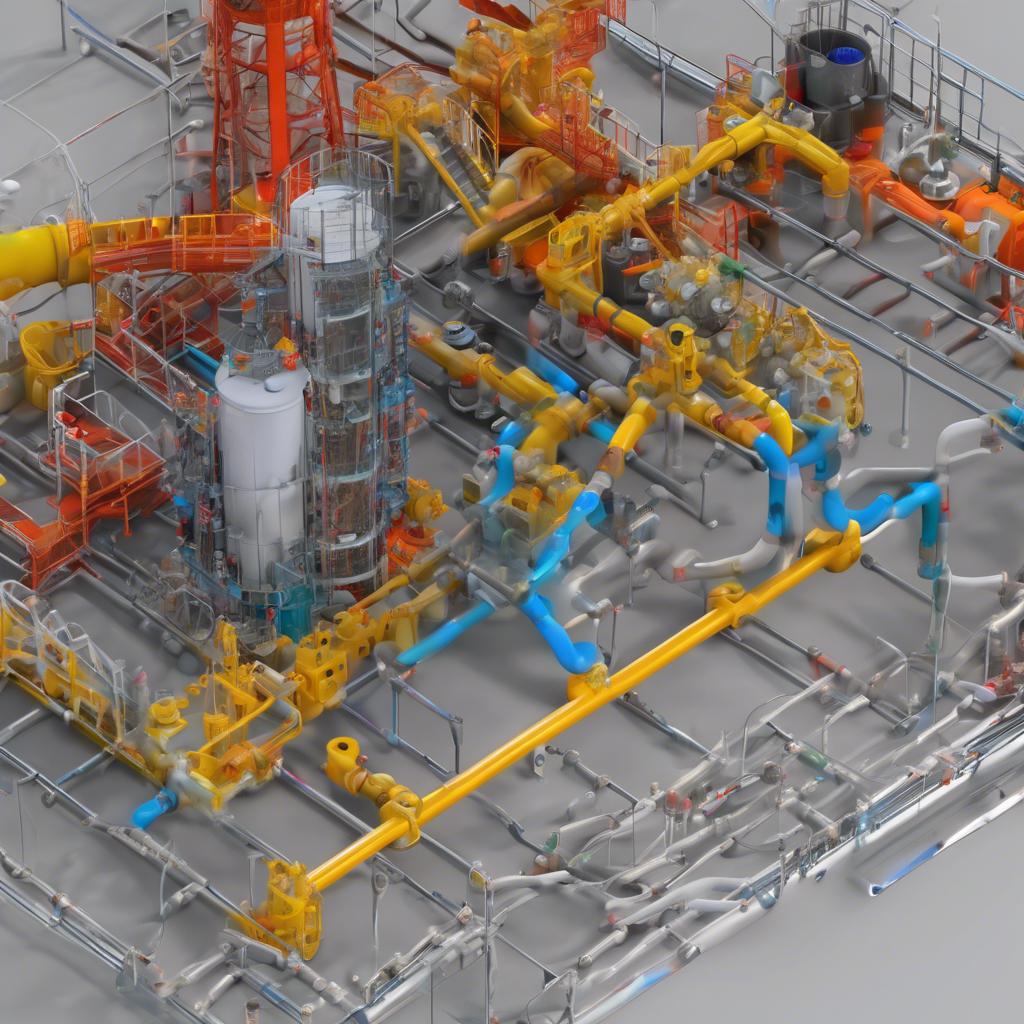

Prevent costly breakdowns and extend the life of your oil field equipment with our AI-powered predictive maintenance system. Identify issues before they become problems. Our solution uses real-time data analytics and machine learning algorithms to anticipate failures, allowing for timely repairs and reduced downtime. By continuously monitoring equipment performance and environmental conditions, we can provide actionable insights that enhance operational efficiency. Implementing our predictive maintenance strategies not only ensures safety but also optimizes maintenance schedules, aligning resources effectively. Experience increased productivity and reduced operating costs with our comprehensive approach to equipment care.

Schedule a DemoOur predictive maintenance platform combines cutting-edge technology with industry expertise to keep your oil equipment running at peak performance. Experience enhanced operational efficiency and reduced downtime with features tailored for the future.

Machine learning algorithms that detect anomalies and predict equipment failures before they happen. Leverage data-driven insights to optimize your maintenance schedules.

Continuous 24/7 monitoring of equipment health with instant alerts when parameters deviate from normal. Stay ahead of potential issues with timely notifications.

Comprehensive visualization of all operational data and equipment health metrics in one place. Analyze trends and make informed decisions quickly.

Robust sensors designed specifically for harsh oil field environments to collect accurate data. Monitor conditions accurately for proactive management.

Customizable reporting with detailed analysis and maintenance recommendations delivered on schedule. Focus on strategic initiatives instead of manual data compilation.

Easy integration with your existing equipment and enterprise management systems. Enhance your operational landscape without significant disruption.

Our streamlined process transforms your maintenance operations from reactive to proactive in four simple steps.

We deploy our industrial-grade IoT sensors on your critical equipment components. These sensors are designed for durability and accuracy, ensuring reliable data collection in even the harshest environments.

Sensors continuously collect operational data like vibration, temperature, and pressure readings. The information is sent in real-time to our cloud-based platform, where it is stored and processed for analysis.

Our AI algorithms analyze the data, learning normal operation patterns and identifying deviations. The system evolves continuously, adapting itself to new data trends, which increases accuracy over time.

System predicts potential failures and sends actionable alerts with maintenance recommendations. Our user-friendly dashboard helps your team prioritize tasks and minimize downtime effectively.

Don't just take our word for it. Hear from oil and gas companies that have transformed their maintenance operations with our solution.

"We've reduced our maintenance costs by 28% in the first year alone. The system has paid for itself multiple times over by preventing two major equipment failures that would have cost us millions."

"The predictive insights from this platform have completely changed how we approach maintenance. Our technicians now know exactly what to focus on, making them much more efficient."

"As a smaller operation, we couldn't afford the downtime we were experiencing. This platform has given us the same level of maintenance intelligence that was previously only available to much larger companies."

"Our experience with this solution has been nothing short of exceptional. The ease of integration and user-friendly interface allowed our team to adapt quickly and start seeing results immediately."

"With this tool, we’ve enhanced our safety protocols significantly. The proactive alerts help us address potential hazards before they escalate, ensuring a safer working environment for all."

Ready to elevate the way you maintain your assets? Embracing a modern maintenance strategy is key to maximizing efficiency and reducing costs. By integrating advanced technologies such as IoT, AI-driven analytics, and real-time monitoring, you can predict equipment failures before they occur and optimize your maintenance schedules. This proactive approach not only enhances operational reliability but also extends the lifespan of your assets, giving you a competitive edge in today's fast-paced market. Don't be left behind—transform your maintenance strategy today and unlock the full potential of your operations.

Subscribe to our newsletter to learn more about predictive maintenance solutions and receive exclusive industry insights.